OmniFold Folder Gluer

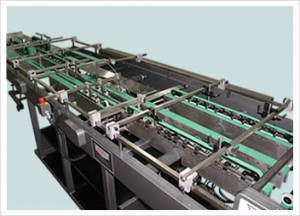

Building on the reputation of the Kluge UniFold, the OmniFold offers the user greater converting capability in combination with improved user-friendly features. These will maximize converting capabilities while minimizing set-up time. Capable of handling a 30″ wide sheet (x 32″ in length), the OmniFold is available with right and left hand side sheet registration, a combination angled or vertical buckle fold unit, flip gate and tab blast. Between the feed section and the combination buckle fold unit, the machine offers 6′ of converting area (with additional 3′, 6′ or 9′ options). Segmented converting tables, encoder based controls and simplified electronics make the OmniFold easier to set up, operate and maintain. Like the Kluge UniFold, the OmniFold is modular in construction, allowing the owner to expand their folder gluer capabilities as needed. Drop-in scoring kit, fold hooks (for auto-lock boxes), tabbing, tipping, onserting and taping units and many more features can be added to increase service offerings to your customers.

- 2″ Welded Steel Frame – Stronger than “bolted” frames

- CE Compliance Package

- Rack and Pinion Elevator Drive – Smooth, low maintenance

- Electrical Controls – Operate the start, stop, jog and speed controls

- High-end 4 or 8 Channel Controller – Operate a variety of devices

- Filler plates – 6″ filler plates provide a base for stock to run along

- Narrow Reinforced Folding Sword Attachment – Glue closer to score

- 7″ Plows – Plow folds small partitions. Required for pre-breaking

- Self Contained Control – For offline transtables and final folds

- Capacity Folder Unit – Fold and glue capacity (or box pocket) folders

- Final Fold – Used to spine fold various pocket folders

Brandtjen & Kluge is a US manufacturer of quality modular folding and gluing equipment for the graphics, mailing and packaging industries. Kluge multi-function folder gluers are quality-built with versatility in mind.

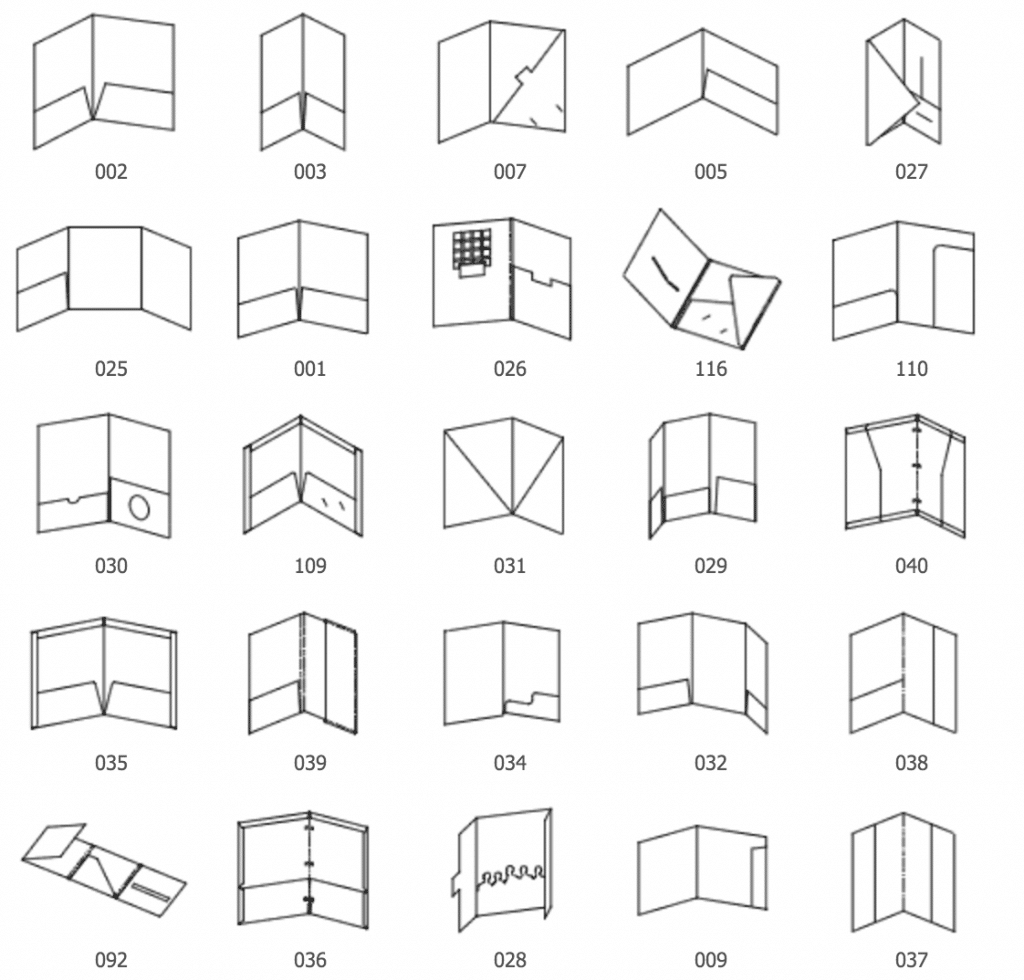

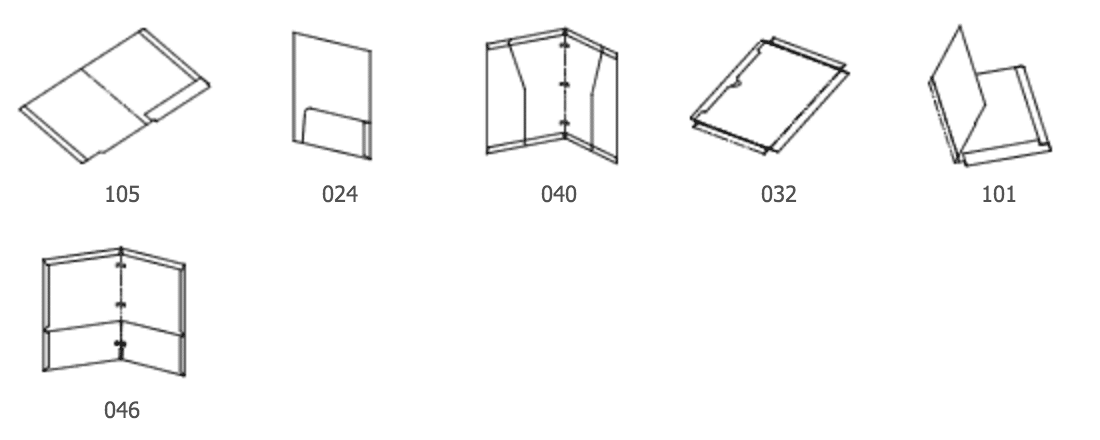

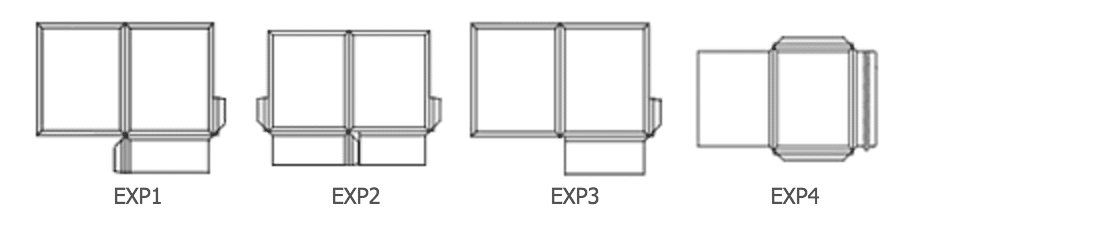

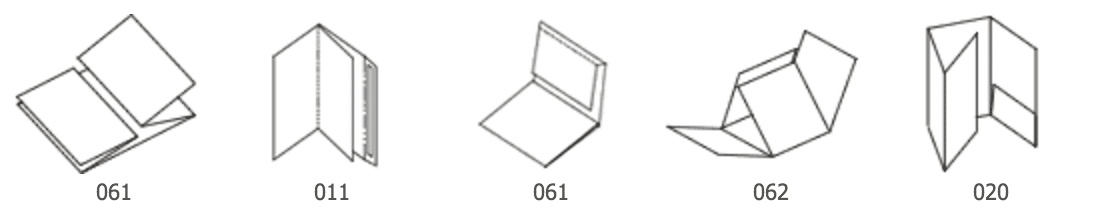

Folding and Gluing. The critical last step in print finishing. Which markets do you serve? Digital Printing? Variable Data Printing? Mailing? Transactional Mailing? Food, Health & Beauty, Pharmaceutical Packaging? Something different? A virtually infinite range of end products can be converted on any one machine. Select your format from the list below for layout drawings, video demonstrations and more details.

Remember, the list below represents only common folder gluer formats, it is not a complete list of the capabilities of our folding and gluing equipment. If you have any questions relating to our line of folder gluers, contact us.

| Omnifold | Engish | Metric |

| Average length (approx) | 23′ – 27′ | 701 – 823 cm |

| Width | 72″ | 183 cm |

| Height | 72″ | 183 cm |

| Maximum sheet size | 30″ x 32″ | 76 x 81 cm |

| Minimum sheet size | 4.75″ w x 3.75″ | 12 x 9.5 cm |

| Stock range (coated or uncoated) | .004″ – .030″ | 60 – 600 gsm |

| Operating speed | 450 fpm | |

| Air | 90 psi @ 15 cfm | |

| Machine power required | 220 – 230V, single-phase, 40 amp |

In general terms the UniFold and OmniFold folder gluers have or can be configured to do nearly the same work. The main benefits of the OmniFold Automatic Folder Gluer are as follows:

- Constructed to be more heavier duty than the UniFold

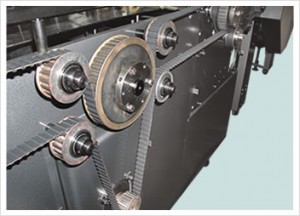

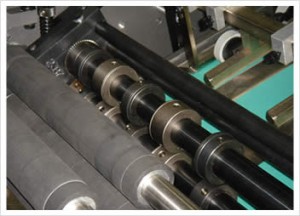

- It is belt driven, offering easier maintenance of drive and product belts

- Utilizes Kluge’s patented bearing bed drives

Why the choice?

The main concept behind designing two machines with similar capabilities and functionality is that the UniFold can be purchased as an entry-level, modular-constructed machine providing the customer with a highly versatile folder gluer with the option to add to as they grow their business and expand their converting services.

On the other hand, the OmniFold has been primarily manufactured for the established business that demands a range of unique features with unmatched versatility and ease of use.

Additional features available for the OmniFold

Although many of the UniFold features cross over to the OmniFold, the OmniFold boasts additional feature benefits to maximise the converting potential of the machine.

Left and Right Registration

With integrated left and right registration the use of the Bump-90 becomes a simple and easy setup. Re-aligning after the 90 degree turn is made easy by dropping in the side guide and marble bar, then skew the belt left or right to guide the sheet. This is a huge time saving feature when converting 3-sided reinforced pocket folders or folders with a vertical and horizontal pockets in one pass.

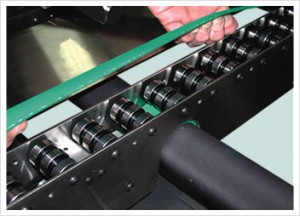

Bearing Bed Drives

By eliminating the friction between drive belts and the table, longer top drives of 18″, 33″ and 36″ lengths can be used for faster make-readies and better sheet control. The Bearing Beds easily lift out of the machine for cleaning and maintenance.

Belt Drives

The entire system is belt driven with easy to access belt tensors. This drive system offers little to no maintenance vs. competing chain drive system or undersized belt driven systems. They are universally preferred on Kluge folder gluer style systems.

Incline Drive

The incline drive can be positioned in angled or horizontal positions to return sheet to entry height after a buckle fold. The feature comprises of gas springs, four 2.5″ wide belts, deflector chute and intermediate drive wheels.

Download product literature for the OmniFold folder gluer.

Kluge folder gluer specifications sheet (44kb)

Folder Gluer Production Format Booklet (86 pages, 2.8mb)

Benefits

Benefits

The Kluge registration feature uses a marble drive with steel balls and skewed belt to direct the stock against the left or register guide. A combination of lightweight and/or fewer balls are used to accommodate various weights of stock. For example, lighter balls are needed for pharmaceutical paper bag products than those needed for 12pt pocket folder applications.

The Kluge registration feature uses a marble drive with steel balls and skewed belt to direct the stock against the left or register guide. A combination of lightweight and/or fewer balls are used to accommodate various weights of stock. For example, lighter balls are needed for pharmaceutical paper bag products than those needed for 12pt pocket folder applications. The entire system is belt driven with easy to access belt tensors.

The entire system is belt driven with easy to access belt tensors. Decrease make-ready time

Decrease make-ready time Kluge folder-gluers can be configured with several different types of glue systems for hot melt gluing, cold glue or fugitive gluing. Depending on your application and control module, several glue heads can be used simultaneously which include a range of melt or stainless steel tanks.

Kluge folder-gluers can be configured with several different types of glue systems for hot melt gluing, cold glue or fugitive gluing. Depending on your application and control module, several glue heads can be used simultaneously which include a range of melt or stainless steel tanks. The Kluge Friction Feeder was designed to continuously feed stocks that otherwise are difficult or impossible to feed with a Vacuum Feed Unit. The Friction Feeder is portable and is designed to be easily removed when the Vacuum Feed Unit is a better choice to feed a specific stock.

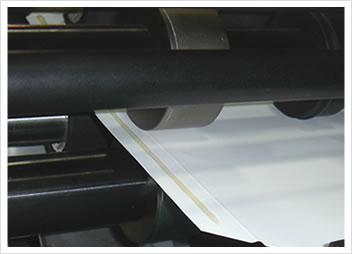

The Kluge Friction Feeder was designed to continuously feed stocks that otherwise are difficult or impossible to feed with a Vacuum Feed Unit. The Friction Feeder is portable and is designed to be easily removed when the Vacuum Feed Unit is a better choice to feed a specific stock. Multiple sheet detector

Multiple sheet detector The Kluge vacuum pile feeder is equipped with a rack-and-pinion drive elevator and laminated feed table. Electronic pile height adjustment and a double sheet detector provide effective control for a variety of products. An air blast bar with dual independent adjustment combined with a double row vacuum wheel mounted on a 7/8″ shaft assures controlled feeding on a wide variety of stocks and formats. Independent bottom sheet supports add to the ComFold’s positive sheet control. A gap control module provides precise control of spacing between sheets; a tab blast module is also included. The converting station is equipped with four 2-1/2″ belts and a top drive wheel system. Fourteen inch long electro-less, nickel-plated tab turning plows assure consistent fold quality. An independent vacuum pump and self-contained blower are provided as standard equipment.

The Kluge vacuum pile feeder is equipped with a rack-and-pinion drive elevator and laminated feed table. Electronic pile height adjustment and a double sheet detector provide effective control for a variety of products. An air blast bar with dual independent adjustment combined with a double row vacuum wheel mounted on a 7/8″ shaft assures controlled feeding on a wide variety of stocks and formats. Independent bottom sheet supports add to the ComFold’s positive sheet control. A gap control module provides precise control of spacing between sheets; a tab blast module is also included. The converting station is equipped with four 2-1/2″ belts and a top drive wheel system. Fourteen inch long electro-less, nickel-plated tab turning plows assure consistent fold quality. An independent vacuum pump and self-contained blower are provided as standard equipment. Benefits

Benefits

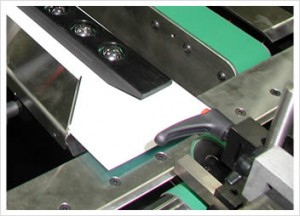

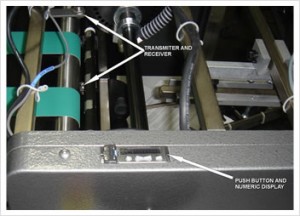

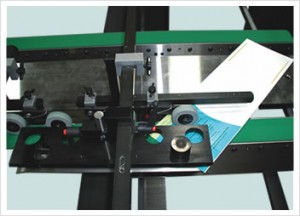

In the past, Kluge folder-gluers have been shipped with a Mechanical Multi-Sheet Detector. Although this was a beneficial feature for detecting multi-fed sheets, the configuration was somewhat cumbersome and could not be applied to smaller jobs. To eliminate these shortcomings and utilize technological advances, Kluge has introduced the Electronic Multi-Sheet Detector (MSD) to its newest folder-gluer, the OmniFold. How Does it Work?The MSD is simple to set up and use. A pair of sensors mounted to a crossbar at the in-feed area scans every sheet that passes between them. These sensors are wired to a control module that can be set to shut the machine off when more than one sheet tries to pass through it. By stopping the machine when multiple sheets are detected, waste and damaged stock is reduced providing larger quantities of usable product while reducing downtime caused by jams. Samples of stock are used to set the sensors precisely for the job that will be run on the machine. What Does it Look Like?

In the past, Kluge folder-gluers have been shipped with a Mechanical Multi-Sheet Detector. Although this was a beneficial feature for detecting multi-fed sheets, the configuration was somewhat cumbersome and could not be applied to smaller jobs. To eliminate these shortcomings and utilize technological advances, Kluge has introduced the Electronic Multi-Sheet Detector (MSD) to its newest folder-gluer, the OmniFold. How Does it Work?The MSD is simple to set up and use. A pair of sensors mounted to a crossbar at the in-feed area scans every sheet that passes between them. These sensors are wired to a control module that can be set to shut the machine off when more than one sheet tries to pass through it. By stopping the machine when multiple sheets are detected, waste and damaged stock is reduced providing larger quantities of usable product while reducing downtime caused by jams. Samples of stock are used to set the sensors precisely for the job that will be run on the machine. What Does it Look Like? While compact in design, and taking up minimal space on the machine, the New MSD replaces the complex setup associated with the mechanical detector with low profile compact sensors. Easy-to-operate push-button controls are mounted to the vacuum feeder structure and include an LCD display for setting verification.Currently the MSD is available as a standard feature for OmniFold folder-gluers. Plans are in the works to incorporate this into the design of the UniFold. Ask us today how the New Electronic Multi-Sheet Detector can reduce waste and damaged stock during production on the OmniFold folder-gluer.

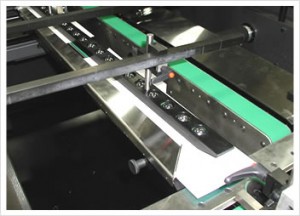

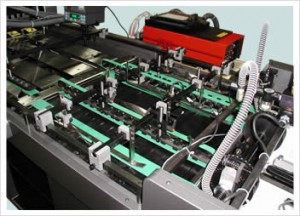

While compact in design, and taking up minimal space on the machine, the New MSD replaces the complex setup associated with the mechanical detector with low profile compact sensors. Easy-to-operate push-button controls are mounted to the vacuum feeder structure and include an LCD display for setting verification.Currently the MSD is available as a standard feature for OmniFold folder-gluers. Plans are in the works to incorporate this into the design of the UniFold. Ask us today how the New Electronic Multi-Sheet Detector can reduce waste and damaged stock during production on the OmniFold folder-gluer. The segmented table makes Kluge folder-gluers more versatile for folding, gluing and converting jobs. The new table design utilizes 2 inch wide segments joined together along the entire table length. These can be removed or replaced as required, to accommodate a wide range of jobs. By removing appropriate segments, the segmented table enables the user to set up a job that will utilize, the tab blaster, air gate, fold hooks and glue system at any area along the table. Clean up time can be reduced by removing segments that would otherwise be dirtied by excess glue, allowing glue waste to be deposited away from the machinery.

The segmented table makes Kluge folder-gluers more versatile for folding, gluing and converting jobs. The new table design utilizes 2 inch wide segments joined together along the entire table length. These can be removed or replaced as required, to accommodate a wide range of jobs. By removing appropriate segments, the segmented table enables the user to set up a job that will utilize, the tab blaster, air gate, fold hooks and glue system at any area along the table. Clean up time can be reduced by removing segments that would otherwise be dirtied by excess glue, allowing glue waste to be deposited away from the machinery. The 9ft inline section, or the IL-9 provides the base unit to which many accessories can be fixed. Included with the IL-9 are filler plates, bearing bed drives, tab turn plows, 18 & 33 inch top belt drives and a tab blaster. IL-3 (3ft) and IL-6 (6ft) models are also available.

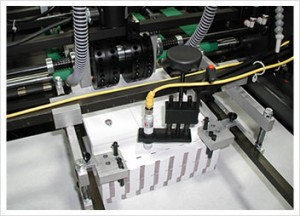

The 9ft inline section, or the IL-9 provides the base unit to which many accessories can be fixed. Included with the IL-9 are filler plates, bearing bed drives, tab turn plows, 18 & 33 inch top belt drives and a tab blaster. IL-3 (3ft) and IL-6 (6ft) models are also available. Like the bucklefolder, the airgate folding kit creates cross folds. However, this feature does not use rollers to convert your product. Instead the airgate uses an air blast from below the machine to push the stock upwards at the correct point in the converting process. The Airgate is used to fold thick stocks or to create cross folds in addition to the bucklefolder, giving a machine greater converting capabilities.

Like the bucklefolder, the airgate folding kit creates cross folds. However, this feature does not use rollers to convert your product. Instead the airgate uses an air blast from below the machine to push the stock upwards at the correct point in the converting process. The Airgate is used to fold thick stocks or to create cross folds in addition to the bucklefolder, giving a machine greater converting capabilities. The Bump 90 attachment rotates the sheet 90 degrees inline, providing accurate alignment for plow folding, taping and two directional gluing.

The Bump 90 attachment rotates the sheet 90 degrees inline, providing accurate alignment for plow folding, taping and two directional gluing. Delivers continuous drive and pressure to products. The continuous drive aspect improves sheet control to all products that require plow, airgate or flipgate folding. Utilizes 1/8″ thick belt with skew adjustment for fine tuning sheet alignment. The Top Belt Drives have independently spring loaded pressure wheels to maintain even and firm pressure with sealed bearings throughout.

Delivers continuous drive and pressure to products. The continuous drive aspect improves sheet control to all products that require plow, airgate or flipgate folding. Utilizes 1/8″ thick belt with skew adjustment for fine tuning sheet alignment. The Top Belt Drives have independently spring loaded pressure wheels to maintain even and firm pressure with sealed bearings throughout. In keeping with our reputation for highly versatile equipment, we have manufactured a fold hook kit for our automatic folder gluers. The optional feature enables users to convert auto-lock bottom boxes and comparable products inline, and at speeds of up to 5,000 + pieces per hour.

In keeping with our reputation for highly versatile equipment, we have manufactured a fold hook kit for our automatic folder gluers. The optional feature enables users to convert auto-lock bottom boxes and comparable products inline, and at speeds of up to 5,000 + pieces per hour. Create cross-folds

Create cross-folds Convenient footprint to better utilize shop floor space

Convenient footprint to better utilize shop floor space Also known as the ‘Pick and Place Unit’, the optional Inserter for Kluge folder gluers allow for placement of an item inline with folding and gluing. In this demonstration a friction-fed tipping unit is mounted to our ComFold folder gluer to onsert CD media onto a flat single pocket CD sleeve. The sleeve is then folded and glued around the CD using hot melt glue and our flip gate feature.

Also known as the ‘Pick and Place Unit’, the optional Inserter for Kluge folder gluers allow for placement of an item inline with folding and gluing. In this demonstration a friction-fed tipping unit is mounted to our ComFold folder gluer to onsert CD media onto a flat single pocket CD sleeve. The sleeve is then folded and glued around the CD using hot melt glue and our flip gate feature. Applying self-adhesive transfer tape or reinforcement tape in-line is easy with the automatic tape head. The tape head can be attached to the converting station in the feeding section or either converting station on the TransTable Unit. The tape head is designed to operate with the standard control module.

Applying self-adhesive transfer tape or reinforcement tape in-line is easy with the automatic tape head. The tape head can be attached to the converting station in the feeding section or either converting station on the TransTable Unit. The tape head is designed to operate with the standard control module. inline with the new Kluge Scoring feature. This new component can be “dropped” into place at up to three locations along the length of the machine. Note: As a standard feature of the OmniFold and ComFold folder gluers, registration can be achieved at each of these three points with the marble drive. The first and second mounting positions are at two places on the converting station ( IL-9 unit). Here, the Scoring feature utilizes existing hole locations for simple set up and to eliminate the manufacturing costs associated with a separate mounting bracket. The third mounting point (not available for the ComFold) is at the angled bucklefold location, where the buckle plate rail is used. In comparison to this quick and simple “drop-in” method, alternative scoring devices currently on the market feature a completely separate unit. Here the Scoring feature has to be rolled into place at the either feeder end of the machine or mid-stream. This results in a cumbersome and inconsistent-placement set up process.

inline with the new Kluge Scoring feature. This new component can be “dropped” into place at up to three locations along the length of the machine. Note: As a standard feature of the OmniFold and ComFold folder gluers, registration can be achieved at each of these three points with the marble drive. The first and second mounting positions are at two places on the converting station ( IL-9 unit). Here, the Scoring feature utilizes existing hole locations for simple set up and to eliminate the manufacturing costs associated with a separate mounting bracket. The third mounting point (not available for the ComFold) is at the angled bucklefold location, where the buckle plate rail is used. In comparison to this quick and simple “drop-in” method, alternative scoring devices currently on the market feature a completely separate unit. Here the Scoring feature has to be rolled into place at the either feeder end of the machine or mid-stream. This results in a cumbersome and inconsistent-placement set up process. scoring is a four-sided reinforced book cover. Here the two reinforced fold tabs on left and right edges of the cover are scored, glued and then folded inline at the bucklefolder location. After a Bump90 (90 degree rotation of the sheet and re-registration) the process is repeated on the top and bottom edges of the piece at the IL-9 position. Finally the book cover is delivered complete on the stacker unit.

scoring is a four-sided reinforced book cover. Here the two reinforced fold tabs on left and right edges of the cover are scored, glued and then folded inline at the bucklefolder location. After a Bump90 (90 degree rotation of the sheet and re-registration) the process is repeated on the top and bottom edges of the piece at the IL-9 position. Finally the book cover is delivered complete on the stacker unit. Vacuum Belt Drives make it possible to drive a product when no top drive wheels or belts can be positioned. Easy like a Bearing Bed Drive, Kluge Vacuum Belt Drives are inter-changeable with our Bearing Bed Drives. Click here to view video of Kluge Vacuum Belt Drives.Contact our sales department for more information at

Vacuum Belt Drives make it possible to drive a product when no top drive wheels or belts can be positioned. Easy like a Bearing Bed Drive, Kluge Vacuum Belt Drives are inter-changeable with our Bearing Bed Drives. Click here to view video of Kluge Vacuum Belt Drives.Contact our sales department for more information at  Kluge’s patented vertical bucklefolder can fold stocks ranging from 8pt to 24pt without causing crows feet, a persistent problem for many trade finishers. For lighter stocks there is a angled bucklefold plate position for greater speeds.

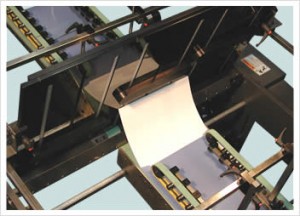

Kluge’s patented vertical bucklefolder can fold stocks ranging from 8pt to 24pt without causing crows feet, a persistent problem for many trade finishers. For lighter stocks there is a angled bucklefold plate position for greater speeds. The incline drive can be positioned in angled or horizontal positions to return sheet to entry height after a buckle fold. The feature comprises of gas springs, four 2.5″ wide belts, deflector chute and intermediate drive wheels.

The incline drive can be positioned in angled or horizontal positions to return sheet to entry height after a buckle fold. The feature comprises of gas springs, four 2.5″ wide belts, deflector chute and intermediate drive wheels. The Kluge Final Fold Unit was designed with a sturdy 2″x 2″ welded tubular steel frame to provide a stable and long lasting unit. The frame serves as the base for a unit that will outperform our previous design by folding thicker stocks thanks to our new center drive belt design.

The Kluge Final Fold Unit was designed with a sturdy 2″x 2″ welded tubular steel frame to provide a stable and long lasting unit. The frame serves as the base for a unit that will outperform our previous design by folding thicker stocks thanks to our new center drive belt design. Stacking and batching is made easy with the Kluge Stacker Unit. An electronic batch counter controls the belt drive providing consistent batching. An electronic totalizing counter keeps track of total production. The stacker height is easily adjusted by a rack-and-pinion drive.

Stacking and batching is made easy with the Kluge Stacker Unit. An electronic batch counter controls the belt drive providing consistent batching. An electronic totalizing counter keeps track of total production. The stacker height is easily adjusted by a rack-and-pinion drive.